The carton and bin conveyor range

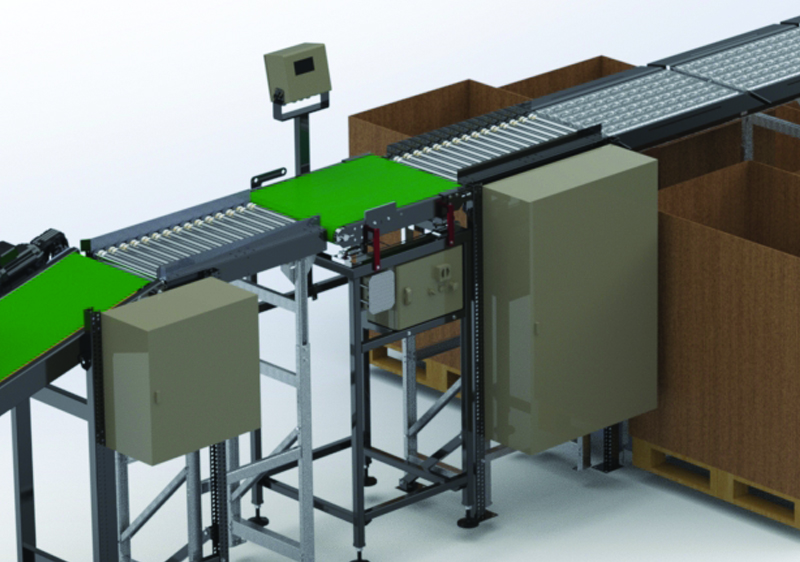

PRODEX designs, manufactures, and installs various types of motorized and non-motorized conveyors for light loads.. Both belt conveyors and roller conveyors are available, according to your specifications. Whether you need to facilitate product handling in your warehouse, improve production line efficiency, or optimize your logistics flow, our conveyors are designed to meet your specific needs.

Indeed, our conveyors for light loads are suitable for handling cartons, parcels, cases, and other flat-bottomed moderate-weight loads. Our conveyor systems help increase productivity and improve ergonomics for your operators.

Our conveyors, light loads transporters, can be used for the transport to the storage area, manufacturing, production line, order picking, packaging and shipping.

We also offer a range of customizable options and accessories to meet your specific requirements in terms of configuration and functionality. By choosing our conveyors for light loads, you also benefit from top-notch technical expertise. Our team of experienced professionals is here to guide you at every step, from design to installation, in order to provide you with a tailored solution that fits your operational environment.

Conveyors

Thanks to its design office, PRODEX designs and manufactures customised cartons conveyors and other light loads, adapted to your constraints of width, length, height, speed, colour, etc.

Our conveyors are designed and manufactured in our factory in Brittany (France). We use high-quality materials, and our conveyors undergo rigorous testing to ensure their durability and optimal performance.

The basic system can be customised according to the conveyor system, the environmental conditions and the type of application.

Different electric drives are used in the conveyor technology: gear motor, motorized rollers. In addition, the weight of the products to be transported can be directly exploited for gravity applications, for example on downhill conveyors.

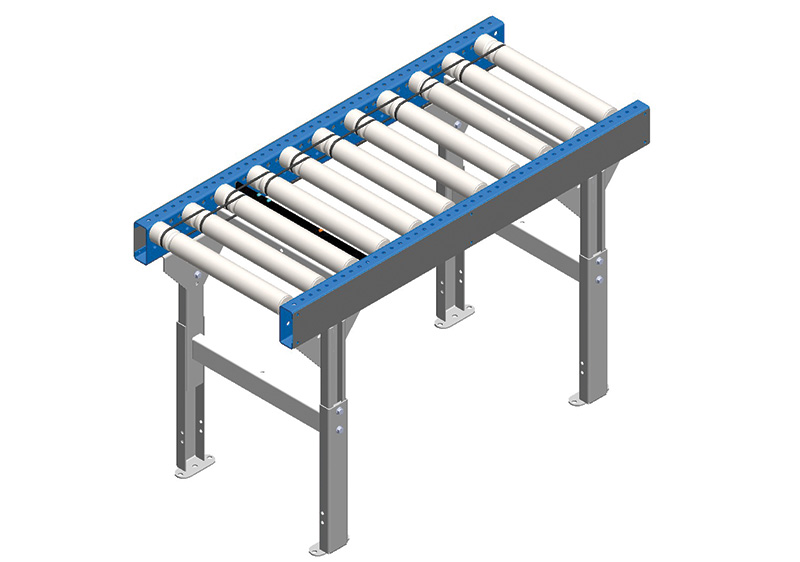

Gravity Roller Conveyor

The gravity roller conveyor is recommended for transporting and accumulating various flat and rigid loads, such as cartons, bins, cases, etc. The gravity rollers facilitate the movement of light loads, allowing for easy and effortless handling for operators.

With its lightweight and modular structure, this conveyor is easy to install and adjust according to your specific needs. Additionally, its maintenance is minimal, reducing operational costs and ensuring continuous efficiency.

The mechanism is simple for the gravity roller conveyor:

Non-motorised rollers are placed on a horizontal conveyor. The operator has to push the item to move it forward. Or the transported loads move by gravity (slope of more than 2%).

(available in stainless steel)

Motorised roller conveyor

With an integrated motorized system, this conveyor ensures a constant and smooth movement of your cartons, packages, and similar loads. This range of motorized roller conveyors (automated conveyor) is advantageous in terms of space efficiency and maintenance (reduced noise level, very little maintenance required). It offers adjustable speed, enabling you to adapt the flow of your products to your specific needs. Furthermore, its modular design facilitates integration into your existing production line, reducing downtime and improving overall efficiency.

This conveyor can be used for various logistics, industrial, and order fulfillment applications. It is the ideal tool for increasing productivity and improving working conditions and ergonomics for your operators. (Available in stainless steel version.)

The automation of our motorized conveyors is integrated by our company DPA Global Solutions.

Extensible conveyor

Thanks to its extendable mechanism, this gravity roller or motorized roller conveyor can be adjusted to different lengths to fit various work areas. Extensible conveyors can be used to handle variable or ephemeral flows. This type of conveyor can be used to optimise working time when (un)loading trucks or containers. You can also use them at the entrances and exits of machines, or to set up a temporary handling flow.

By extending or retracting the conveyor according to your needs, you optimize space utilization and enhance the productivity of your operations.

Our extendable conveyor is designed to be user-friendly and easy to configure. Its quick deployment and easy setup save you valuable time and enable you to quickly adapt your logistics flow to meet your company’s requirements.

The automation of our motorized extendable conveyors is integrated by our company, DPA Global Solutions.

Belt conveyors

Discover the versatility of our belt conveyor. This efficient transport solution provides smooth handling of light loads with its robust and reliable conveyor belt. The advantage of the belt conveyor is that it can be adapted to a wide range of items, flat bottom or not, non packaged items, plastic boxes or cartons. This conveyor is adapted for all areas of a logistics centre or industrial company: reception, production, storage, order picking and shipping.

It ensures continuous and smooth transport of your products, ensuring a seamless flow within your production line. Its conveyor belt enables efficient handling of cartons, packages, and other light loads, thereby enhancing the efficiency of your logistics operations.

Its modular design allows for easy adaptation to different lengths and widths, meeting the specific requirements of your workspace.

The automation of our belt conveyors is integrated by our company DPA Global Solutions.

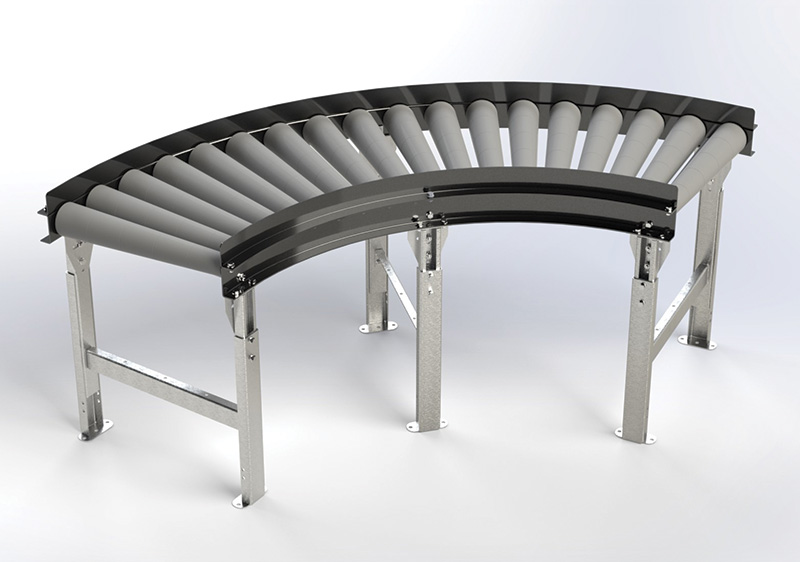

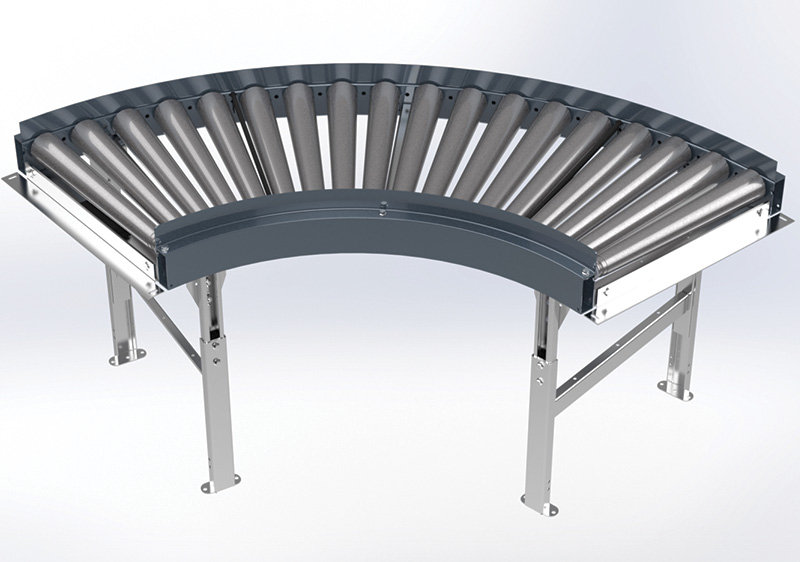

PRODEX also designs curved conveyors (45° to 90°) and 45° angle conveyors to ensure the change of direction of your conveyor lines or to make a complete loop, while ensuring the continuity and fluidity of your processes.

Conveyor accessories

PRODEX proposes accessories, additional equipment to be integrated into your conveyor lines, and adapted to your activity.

Several options are possible depending on the conveyor equipment: lateral guidance, special feet, specific width, specific painting, fixed or retractable stop bump, etc.

Ball tables

Ball tables increase the ergonomics of the workplaces. The operator can easily rotate or transfer cartons and containers. The load must have a rigid flat bottom. PRODEX can integrate the ball table into a free roller conveyor or motorised roller conveyor line.

Free rollers gate

The swing or lift roller gate enables for easy passage of personnel and vehicles.

The free roller gate ensures easy movement of staff between conveyor lines. It can be fitted to a fixed element with free rollers or motorised rollers.

Weighing post

The conveyor weighing station enables you to directly weigh your bins, boxes and products transported by the conveyor. This conveyor weighing equipment weighs loads of up to 60 kg with an accuracy of 1 gram.

Option: Pivoting wheels with brake.

Lifting table

The elevating table is a piece of equipment that facilitates the loading and unloading of your boxes, bins and all types of goods at height. This automated system saves time for the handling of boxes by the operator (reduces the risk of musculoskeletal disorders).

Documentation

You like to learn more about our products and services? Download our brochure in one click.